Remove RFQ Item

New Products Catalog

Remove RFQ Item

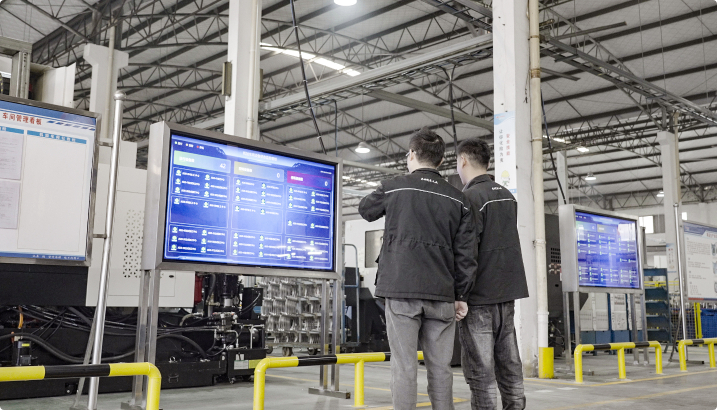

The Hetian Technical Center performs synchronized validation from raw materials to product mechanical, environmental, and life testing. Equipped with robust simultaneous engineering capabilities and mold design/manufacturing expertise, it effectively addresses evolving end-user requirements.

Hetian Automotive deploys a 65-member R&D team with OEM simultaneous development capabilities. Leveraging a national CNAS laboratory and provincial technology center, it rapidly responds to German/American/Japanese vehicle platform requirements. Hetian has chaired 2 national standards and 1 industry standard, while contributing to 6 national/industry standards, enabling full-cycle collaboration from design to mass production for products like chassis dampers and lightweight aluminum forgings.

CAE Structural Analysis - Ball Pins/Sockets/Dust Boots

Critical Point & Material Development

DEFORM™ Simulation - Aluminum Forging Process